|

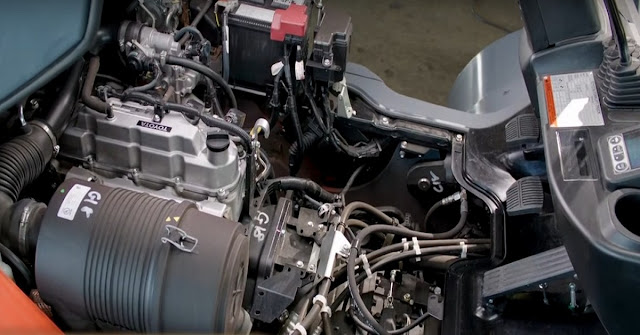

| Internal combustion forklift |

Types of forklift engines explained: Electrical and internal combustion and which is the best?

Industrial forklifts are divided into two categories: electric combustion and internal combustion (IC). The types of forklift engines determine the operation of the forklift where it can be used (inside or outside), it is carrying capacity and overall performance.

Powered by lead-acid batteries, various types of forklifts are electric: forklifts, scissors, pickers, stacker, truck reach, and jack. Electric forklifts are mainly used indoors even on flat surfaces.

The initial cost of electric forklifts tends to be higher than most forklift trucks, but annual fuel and maintenance costs are lower over time. Electric forklift batteries last 6 consecutive hours or 8 hours with 2 to 3 breaks. Battery charge determines lift capacity: A full-load forklift operates at full capacity, while low load reduces power. Warehouses and distribution centers that consume power for more than 7 consecutive hours maintain the battery at an additional cost. Although electric devices are easier to maintain than integrated circuits, they are not recommended for continuous operation of loads of more than 15,000 pounds. The battery prevents harmful vapor emissions and is recommended for equipment in the food and health care industries.

Internal combustion engines use fossil fuels such as gas, propane and diesel. There are several types of forklift CI: tire forklift, rough terrain, scissor lift, telehandler, and elevator. Forklift IC is mainly used for outdoor applications.

The fuel from the lift truck drives the lift longer than the electric pallet truck (LP tank = 8 consecutive hours) and can be refilled in less than 10 minutes. Forklift ICs are stronger than electric forklifts, but their emissions from harmful fumes (eg carbon monoxide) are not ideal for indoor applications. However, LP forklifts can be used indoors with adequate ventilation and large aisles. Forklift ICs do more than just an electric truck with a load of more than 20,000 pounds. Although the cost of an internal combustion engine is lower than electricity, this forklift requires more regular maintenance and higher fuel prices.

With rising gasoline prices and the "go green" movement, forklift brands such as Toyota, Mitsubishi, Linde and Yale are developing alternative fuels to build "green trucks" to reduce the carbon footprint of the industrial sector. The development of gas and hydrogen batteries has been in focus for three years.

In 2010, the BMW Manufacturing Company announced for the first time, together with Linde brand forklift manufacturers, to develop hydrogen forklift trucks and hydrogen fueling stations for the operation of their forklift fleet. The BMW sports car factory in Spartanburg, South Carolina employs more than 100 hydrogen forklift trucks in just two years.

Wholesale stores Whole Foods, Walmart and Wegman also reported the use of hydrogen cell forklifts. Since 2010 is an extraordinary year for hydrogen forklift trucks, why is this forklift not sold to local forklift dealers, which are sold to small and medium businesses? Are ecological forklifts too expensive for the average Joe? While these branded manufacturers continue to experiment with hydrogen fuel cells, other brands think on a smaller scale. Hyster, one of the most popular brands, is currently restructuring the current model design to reuse energy and reduce smoke emissions.

Read more How a forklift works

1 Comments

Now I know the difference. Thanks for sharing!

ReplyDelete